Determining The Thickness Of Glass

As with other materials used in construction, the mechanical strength of glass can be defined as its resistance to loading

Glass is an almost perfectly elastic material. In other words, when loads are applied to glass it will not suffer any permanent deformation, it will always return to its original dimensions irrespective of the number of times it is deformed.

This makes glass a particularly suitable material for use in construction. However, another property of glass is brittleness, which means that it can fracture without warning.

It is therefore vital to ensure that the correct type and thickness of glass is specified for each individual application.

Despite its brittle nature, glass is an enormously strong material. Under compression loads, a 1 cm cube of glass can withstand up to 10 tonnes before breaking.

Therefore, in theory it should be very difficult to break a sheet of glass, but it is rare to encounter situations where compressive loads act alone – there must be other factors at work.

Whilst the resistance of glass to compression alone is extremely high, the compression will also generate tensile stresses and its resistance to tensile forces is somewhat lower.

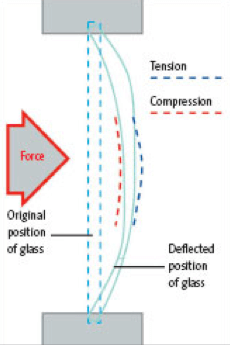

When loads are applied to glass, it causes both compression and tensile stresses as illustrated in the diagram. The face of the glass that has the load imposed on it is subject to compressive stresses for which glass has a high resistance. The opposite face has tensile stresses applied to it for which glass has a lower resistance.

The surface of glass is covered in microscopic flaws known as Griffith’s Flaws. The flaws are naturally present in the surface of the glass and can also be caused by normal everyday handling, cleaning or processing. The number and distribution of these flaws is critical to the point where breakage will occur.

Eventually, depending on the stress level caused by the applied load, the flaws will lead to a crack developing, which ultimately results in failure.

The majority of loads which glass has to withstand are caused by bending and probably the most important external factor in specifying a suitable glass thickness is the design wind load. dualseal can give general guidance on short duration wind load pressures.

The actual working wind load pressure for each individual application should be determined according to EN 1991-1-4.

Careful and informed specification of glass types and thicknesses not only provides confidence in the strength of glass and it’s resistance to breakage but also ensures that the glass does not deflect to such a degree that it is visually disturbing to the onlooker.

This will also help to prevent premature degradation of the glazing sealants and compounds used in the installation.

For this reason stress analysis calculations performed by dualseal take into account both the stress and sensible deflection limits of glass specifications. Another factor to consider is the duration of the imposed loads.

Glass is resistant to loads of short duration, quickly returning to its original shape as mentioned earlier.

The same or even lower loads however, could lead to the failure of the glass if imposed for a greater length of time.

For example in addition to wind loads, inclined glazing has to be able to support its own weight and consideration also has to be given to loads that could be caused by snow, the appropriate loads are determined with EB 1991-1-3.

Where glass acts as guarding differences in finished floor level, the glass thickness is determined from the loads in EN 1991-1-1, the National Annex and PD 6688.

In the case of insulating glass units the environmental loads need to be considered, particularly barometric pressure and unit cavity temperatures, as these may limit the maximum glass dimensions and minimum cavity width, see ‘Glass Thickness in Insulating Glass’ in the download section.

From relatively simple patent glazing to curtain walling and high specification technologically advanced structural bolted systems, we can provide safe and practical solutions for overhead glazing.